The global manufacturing and port industries have made significant strides in recent years. New technologies, including the Industrial Internet of Things (IIoT) and smart automation, have transformed traditional linear manufacturing supply chains into intelligent, dynamic, and flexible systems. Meanwhile, ports have become more sophisticated, with an increasing focus on optimizing the movement of goods, reducing downtime, and improving worker safety.

One key technology driving these changes is private wireless networks. With a private network, ports and manufacturing facilities can create intelligent, dynamic, and flexible systems that offer a range of benefits, including speed, reliability, security, mobility, and full site coverage. However, these ports and manufacturers cannot always access licensed spectrum, and public networks cannot always meet the coverage and reliability requirements of ports with complex environments.

MFA, the Alliance for private networks, is championing the global industry adoption of private networks in any available spectrum using Uni5G™ technology blueprints for 5G and MFA-defined MulteFire® specifications for 4G/LTE. MFA’s Uni5G technology blueprints and MulteFire specifications can help port authorities and manufacturing enterprises unlock and easily deploy and operate their own secure 5G or 4G/LTE private network to accelerate their digital transformation using any available spectrum including locally licensed, shared, and unlicensed spectrum.

For port and terminal operators, private networks offer significant benefits. They can increase productivity through more automation and remote control, enable true, transparent visibility into everything in the terminal, and reduce downtime with seamless handover and extended coverage across the entire port. Private networks also allow for the deployment of AI to solve efficiency and even address safety issues.

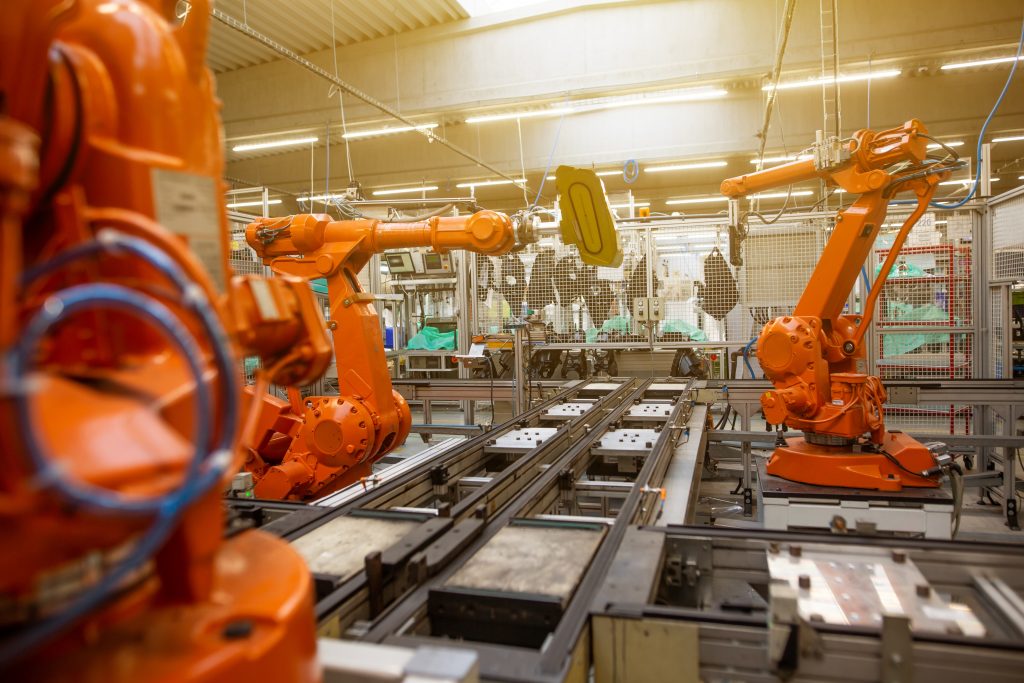

Manufacturing enterprises can also benefit from private wireless networks that allow them to enable smart manufacturing. Intelligent automated guided vehicles (AGVs) and improved augmented and virtual reality overlays become possible with a private network. With a private network, reconfiguring factory floors becomes easier, reducing costly product stops typical in fixed wired environments. Private networks also allow manufacturers to analyze, predict, and prescribe processes for better performance, longer maintenance cycles, and energy savings.

Private networks offer a simple, productive, and efficient solution that manufacturing and port facilities require, and MFA is working to help simplify the deployment of these private networks through its growing ecosystem of members. To learn more, watch MFA’s port and manufacturing videos for specific use case examples of how MFA can help you experience the full benefits of a private network today.